Our Products Range

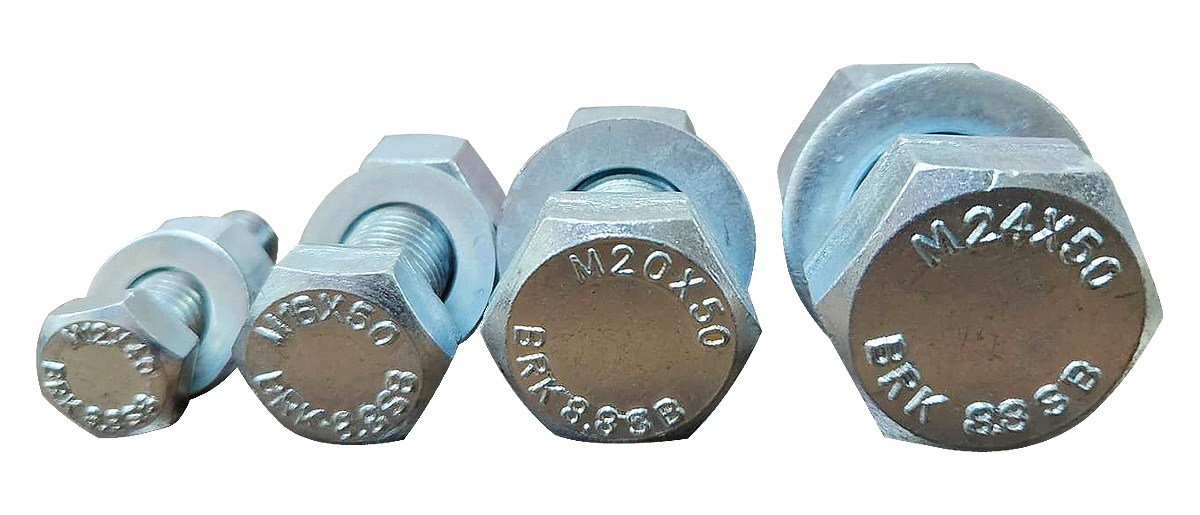

Non-preloaded Structural Bolt Assembly BS EN 15048 (CE & UKCA Certified)

Equivalent Standard: ISO 7412

Heavy Duty non-preloaded Structural Bolt Manufacturer with UKCA & CE Certification in BS EN 15048 Standard.

For EN 15048 non-preloaded Structural bolt assembly, BRK strictly meets Below Guidlines.

The Structure Bolt, Nut and Washer assembly is supplied by one manufacturer who is responsible for the function of the assembly.

All the Structural Bolting Assembly Components are Marked with the BRK Brand.

The coating of the assembly is under the control of the manufacturer. We have in house Zinc Plating Plant.

We manufacturers Structural Bolt assembly in Grade 5.6, 8.8 & 10.9 material.

BRK non-preloaded Structural Bolt assembly is Perfect for Mounting wind tower, nuclear power, railway, automotive industry, construction, electronic industry.

- EN 15048

- Material Grade: 5.6, 5.8, 6.8, 8.8, 10.9

- Finish: Self, Black, Bright Zinc, Hot Dip Galvanized

- Thread: METRIC

EN 15048

BS EN 15048 is a series of the European standard for non-preloaded structural bolting assemblies that discusses the features of bolts to strengthen the Structural construction joints.

BS EN 15048-1 are designed to be used in structural bolting connections for shear and/or tensile loading.

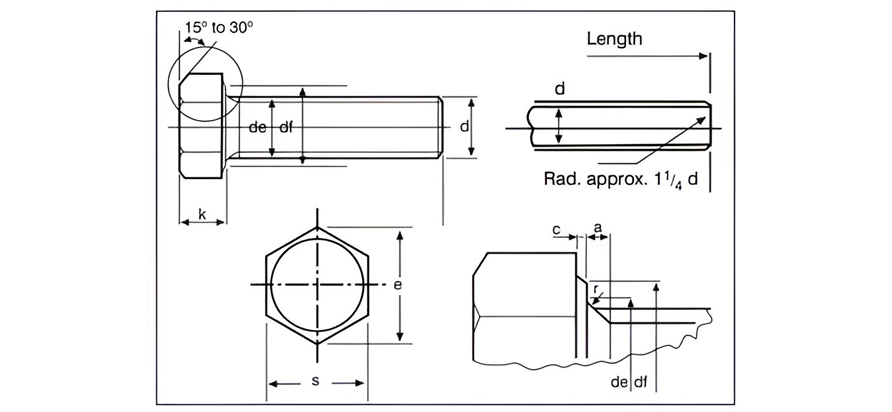

BRK EN 15048 structural bolting assemblies is manufactured from carbon and alloy steel Grade of 5.6, 8.8, 10.9, intended for use in steel structures and occasionally in other structures requiring similar techniques. The BS EN 15048 standard details the specifications for non-preloaded structural bolts, nuts, and washers used in steel construction provides guidelines to ensure their reliability and safety in various structural applications. These standard covers a range of parameters including mechanical properties, dimensions, material Grade, Coatings for non-preloaded structural bolting assemblies. Specific criteria for Structure bolt diameters, thread lengths, head dimensions, and performance grades are outlined in Non Pre-Load Bolts EN 15048 Standard Guidelines.

Technical Specification for Non Preloaded Structural Bolt Assemblies (EN 15048)

| BS EN 15048 Fully Threaded Set screw Dimensions. Classes 8.8 & 10.9 | |||||||

| Nom. Dia. (d) | M12 | M16 | M20 | M24 | M30 | M36 | |

| Thread Pitch | 1.75 | 2.00 | 2.50 | 3.00 | 3.50 | 4.00 | |

| a | Max. | 5.25 | 6.00 | 7.50 | 9.00 | 10.50 | 12.00 |

| s | Min. | 17.57 | 23.16 | 29.16 | 35.00 | 45.00 | 53.80 |

| Max. | 18.00 | 24.00 | 30.00 | 36.00 | 46.00 | 55.00 | |

| e | Min. | 19.85 | 26.17 | 32.95 | 39.55 | 50.85 | 60.79 |

| df | Min. | 16.47 | 22.00 | 27.70 | 33.25 | 42.75 | 51.11 |

| c | Min. | 0.15 | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

| Max. | 0.60 | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | |

| r | Min. | 0.60 | 0.60 | 0.80 | 0.80 | 1.00 | 1.00 |

| de | Max. | 13.70 | 17.70 | 22.40 | 26.40 | 33.40 | 39.40 |

| k | Min. | 7.32 | 9.71 | 12.15 | 14.65 | 18.28 | 22.08 |

| Max. | 7.68 | 10.29 | 12.85 | 15.35 | 19.12 | 22.92 | |

| Product Characteristic | Standard | |

| Fully Threaded Setscrews | ||

| General Requirements | ISO 4017 | |

| Materials & Manufacture | ISO 898-1 Classes 8.8 & 10.9 | |

| Finish / Coatings | Zinc Electroplated | BS 7371-3 or BS EN ISO 4042 |

| Hot Dip Galvanized | BS 7371-6 or BS EN ISO 10684 | |

| Mechanical Properties | ISO 898-1 Classes 8.8 & 10.9 | |

| Dimensions & Tolerances | ISO 4017 | |

| Threads | ISO 965-2 Class 6G | |

| Bolt Thread Diameter | Tensile Strength | Proof Load | Elongation | Hardness Rockwell HRC | |

| N/mm2 min. | N/mm2 min. | % Min. | Min. | Max. | |

| M12 | 800 | 660 | 12 | 23 | 34 |

| M16 | 830 | 660 | 12 | 23 | 34 |

| M20 | 830 | 660 | 12 | 23 | 34 |

| M22 | 830 | 660 | 12 | 23 | 34 |

| M24 | 830 | 660 | 12 | 23 | 34 |

| M27 | 830 | 660 | 12 | 23 | 34 |

| M30 | 830 | 660 | 12 | 23 | 34 |

| M36 | 830 | 660 | 12 | 23 | 34 |

| EN 15048 Assemblies also require a Charpy Impact Test to EN 10045-1 | |||||

BS EN 15048 Nut Dimensions

| Nominal size and thread diameter d | Pitch of thread p | Width across flats s | Width across corners e | Thickness of nut m | ||

| Max. | Min. | Min. | Max. | Min. | ||

| M12 | 1.75 | 18.00 | 17.57 | 21.10 | 10.80 | 10.37 |

| M16 | 2.00 | 24.00 | 23.67 | 26.75 | 14.80 | 14.10 |

| M20 | 2.50 | 30.00 | 29.16 | 32.95 | 18.00 | 16.90 |

| M24 | 3.00 | 36.00 | 35.00 | 39.55 | 21.50 | 20.20 |

| M30 | 3.50 | 46.00 | 45.00 | 50.85 | 25.60 | 24.30 |

| M36 | 4.00 | 55.00 | 53.80 | 60.79 | 31.00 | 29.40 |

| Product Characteristic | Standard | |

| Nuts | ||

| General Requirements | ISO 4032 & 4034 | |

| Materials & Manufacture | ISO 4032 & 4034 Class 8, 10 & 12 | |

| Finish / Coatings |

Self Colour / Black | ISO 4032 & 4034 |

| Zinc Electroplated | BS 7371-3 or BS EN ISO 4042 | |

| Hot Dip Galvanized | BS 7371-6 or BS EN ISO 10684 | |

| Mechanical Properties |

Self Colour / Zinc Electroplated | ISO 4032 & 4034 Class 8 |

| Hot Dip Galvanized | ISO 4032 & 4034 Class 10 & 12 | |

| Dimensions & Tolerances | ISO 4032 & 4034 | |

| Threads | Self Colour / Zinc Electroplated | ISO 965-2 Class 6H |

| Hot Dip Galvanized | ISO 965-2 Class 6AZ | |

| Product Marking | BS EN ISO 898-2 | |

BS EN 15048 Proof load values of property classes 8 & 10 nuts

| Nut thread Diameter |

Stress Area Test Mandrel |

Property Class | |

| 8 | 10 | ||

| Tolerance class 6H (1) |

Tolerance class 6AZ (2) |

||

| mm2 | Proof Load kN | Proof Load kN | |

| M12 | 84.3 | 67 | 78.1 |

| M16 | 157 | 125 | 150 |

| M20 | 245 | 196 | 236 |

| M24 | 353 | 282 | 342 |

| M30 | 561 | 448 | 551 |

| M36 | 817 | 653 | 808 |

| 6H (1) is the tolerance class for self colour & Zinc plated nuts. | |||

| 6AZ (2) is the tolerance class for hot dip galvanized nuts | |||

| Nominal size of bolt or screw | EN ISO 7089 – 2000 | |||||

| Inside Diameter d1 | Outside Diameter d2 | Thickness s | ||||

| Max. | Min. | Max. | Min. | Max. | Min. | |

| M12 | 13.93 | 13.50 | 24.00 | 22.70 | 2.80 | 2.20 |

| M16 | 17.93 | 17.50 | 30.00 | 28.70 | 3.60 | 2.40 |

| M20 | 22.52 | 22.00 | 37.00 | 35.40 | 3.60 | 2.40 |

| M24 | 26.52 | 26.00 | 44.00 | 42.40 | 4.60 | 3.40 |

| M30 | 33.62 | 33.00 | 56.00 | 54.10 | 4.60 | 3.40 |

| M36 | 40.00 | 39.00 | 66.00 | 64.10 | 6.00 | 4.00 |

| Product Characteristic | Standard | |

| Washers | ||

| General Requirements | EN ISO 7089 – 2000 | |

| Materials & Manufacture | EN ISO 7089 – 2000 | |

| Finish / Coatings |

Self Colours / Black | EN ISO 7089 – 2000 |

| Zinc Electroplated | BS 7371-3 or BS EN ISO 4042 | |

| Hot Dip Galvanized | BS 7371-6 or BS EN ISO 10684 | |

| Dimensions & Tolerances | EN ISO 7089 – 2000 | |